TPI Bio-San is a dark, naturally-occurring, dark-water, high-quality microorganism used for wastewater treatment. Digest waste Reduce mosquitoes and flies, reduce odors, unpleasant odors caused by hydrogen sulfide. Ammonia gas, etc. The major microbial groups are:

- Organic microorganisms such as starch, protein

- celluloseOrganic microorganisms such as starch, protein

- celluloseSulfate compound microorganismGroup of photosynthetic microorganisms

Scope of use

- Used in both aerated and anaerobic wastewater treatment systems to effectively reduce BOD and COD.

- Wastewater treatment in livestock farms

- Digested the waste in the septic tank. Make drains do not block.

- Wastewater from animal shed

Liquid bath soap and Hand Soap. Gently cleanses thoroughly. Soft bubble cream Relaxed fragrance, easy to wash. Maintain moisture Smooth on the skin. Free from alcohol Which cause irritation.

Liquid bath soap and Hand Soap. Gently cleanses thoroughly. Soft bubble cream Relaxed fragrance, easy to wash. Maintain moisture Smooth on the skin. Free from alcohol Which cause irritation.

TPI Blocks are new innovative products under the development of TPI Polene Public Company Limited for the purposes of construction and decoration. The blocks are manufactured by combining premium quality ingredients with TPI Portland cement. After being molded, the blocks are placed in an autoclaved system, the latest and most effective technology used in manufacturing lightweight blocks, so the results are high strength and durable blocks. Thus, users are reassured that TPI Blocks have finest quality and durability.

With high standard quality control, TPI Blocks are guaranteed with the industrial standard of TIS.1505-2541, which is certified by Thai Industrial Standards Institute (TISI). The logo is granted for autoclaved aerated lightweight concrete blocks that are warranted with international standards including:

|

BS EN 771-4 |

: Specification for masonry units |

|

|

BS EN 772-1 |

: Determination of compressive strength |

|

|

BS EN 772-13 |

: Determination of net and gross dry density |

|

|

BS EN 772-16 |

: Determination of dimensions |

Special-purpose mortar used with fiber cement to plaster both fiber board type of flat and groove due to it's very easy to work slip. Causing work smooth and retain for screws fixing the fiber cement. Flexibility and high adhesion, no cracks, no cracks, no sanding to sand easily.

>>Shop Now<<

SCOPE OF USE

Used for plastering, sealing and grooving. Keep the head of the fiber cement screws. And some plaster is Skim Coat.

RAW MATERIAL

- TPI Portland Type 1 Cement according to ASTM C-150 and TIS 15-2555

- Fine Crushed Limestone through the process of drying and size.

- Additives Extra high adhesion strength.

HOW TO PREPARE THE SKIN AND USE.

- In the case of plastered joints with a grooved sheet of fiber cement.

- Clean the area where the cementitious cementitious bonding is to be applied. By eliminating dust and what can affect adhesion.

- Mix cement plasterboard, seal fiber cement joints with clean water. Using a ratio of 1 kg of water per 300 ml of water, mix well. Do not leave the lumps that are not into the water.

- Apply to the joints of fiber cement sheets using a trowel. The plaster is smooth and full.

- Allow the mortar to dry and harden for about 2 hours, then use sandpaper to smooth the surface.

- In case of plastering joint of groove and mortice

- Clean the area where the cementitious cementitious bonding is to be applied. By eliminating dust and what can affect adhesion.

- Mix cement plasterboard, seal fiber cement joints with clean water. Using a ratio of 1 kg of water per 300 ml of water, mix well. Do not leave the lumps that are not into the water.

- In the case of Fiber Mesh, the mixed mortar is used to seal the fiber cement sheet. Use a trowel plaster to smooth and full seam before then close Fiber Mesh by pressing smooth. Close to the mortar to keep track of it. Leave it for about 1 hour.

- Plastered with lime cement joints, fiber cement Plastered smoothly with grooved grooves of fiber cement.

- Allow the mortar to dry and harden for about 2 hours. To smooth the surface.

- Screw head screws of fiber cement.

- Always keep the screw heads always in the same plane as the surface of the fiber cement board.

- Clean the area where the cementitious cementitious bonding is to be applied. By eliminating dust and what can affect adhesion.

- Mix mortar, fiber cement with clean water. Using a ratio of 1 kg of water per 300 ml of water, mix well. Do not leave the lumps that are not into the water.

- Put on the groove of the screw head to full. Using a rubber trowel or trowel.

- Allow the mortar to dry and harden for about 2 hours, then use sandpaper to smooth the surface.

In This Category Other Categories: «Well, TPI's board."

New Choice For Several Applications

- Floor

- Wall

- Decoration

- Classic Series ( Clear coated surface)

- Classic Series (Non-coated surface)

TPI DECO BOARD is a product under TPI fiber cement line, produced by mixing high quality

TPI Portland and natural fiber. By using high technology, TPI DECO BOARD has high resistance

to different weather conditions and easy-to-install. So it can be used for floor, wall and decoration.

There are 2 surfaces such as clear coated and non-coated surface that can be used for both

interior and exterior applications.

Size Thickness and Weight

|

Standard Size |

1200 mm. x 2400 mm. |

||||||||

|

Thickness (mm.) |

6 |

8 |

10 |

12 |

14 |

16 |

18 |

20 |

24 |

|

Weight (kg.) |

31.8 |

42.4 |

53.0 |

63.6 |

74.2 |

84.8 |

95.4 |

106.0 |

127.2 |

Installing Applications

|

Installing Applications |

Thickness (mm.) |

|||||||

|

6 |

8 |

10 |

12 |

16 |

18 |

20 |

24 |

|

|

Raised Floor / Elevated Floor |

|

|

|

|

X |

X |

X |

X |

|

Exterior and Interior Wall and Ceiling |

X |

|

|

|

|

|

|

|

|

Exposed Concrete Surface Partition |

X |

X |

X |

X |

|

|

|

|

|

Subfloor / Subwall for ceramic tile |

|

|

X |

X |

X |

|

|

|

|

Floor Underlayment |

|

X |

X |

X |

|

|

|

|

|

Subroof |

|

|

X |

X |

|

|

|

|

|

Residential Exterior Wall |

|

X |

X |

X |

|

|

|

|

|

Low-Rise Building Exterior Wall |

|

|

X |

X |

|

|

|

|

|

Exterior Exposed Concrete Surface Wall |

|

X |

X |

X |

|

|

|

|

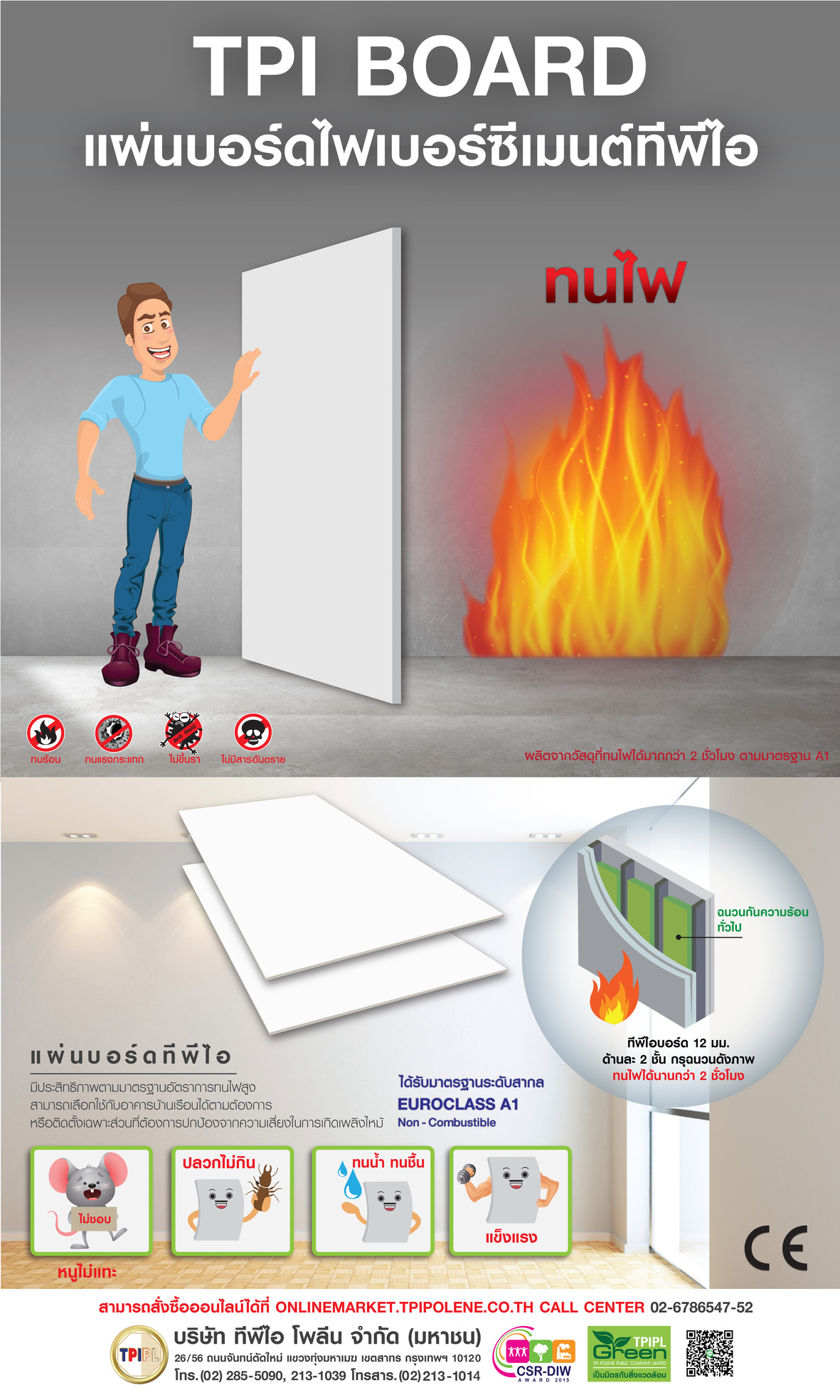

“TPI Board” is a product under TPI fiber product line, manufactured with autoclave technology to compress high quality TPI Portland cement with natural fibers. The results of the process are the eco-friendly. lightweight and high durable fiber boards that are suitable for construction and decorative applications. Also, TPI Fiber Cement Boards are easy-to-install and have a high resistance to different weather conditions so they can be used for both interior and exterior applications, which make them a very cost-effective and time-saving material.

>>Shop Now<<

Characteristic :

√ High Heat and Humidity Resistant

√ High lmpact Resistant

√ Non-asbestos

√ Safe from Termites and Mold

√ High Fire Resistant and Nonflammable

√ Easy-to-lnstall

√ Strong, Long-lasting and Non-shrinking

TPI BOARD for FLOORING

TPI Flooring Boards have high density as composed of the best quality TPI cement. With the attributes, the boards can bear loads of weight and will not be ruined by termites or other pest . Also, the boards do not absorb moisture so they will not swell or mold, which can extend their life expectancy to the maximum level. The surface of TPI Flooring Boards is so smooth and flat that they can be used as the floor itself or used to adjust the level of the floor before easily flooring with parquet, laminate, tiles, or carpet.

|

Edge |

Thickness (cm.) |

Dimension (cm.) |

Weight (kg.) |

|

Smooth Edge |

0.8 |

120 x 240 |

34.4 |

|

1.0 |

120 x 240 |

43.1 |

|

|

1.2 |

120 x 240 |

51.7 |

|

|

1.6 |

120 x 240 |

74.2 |

|

|

1.8 |

120 x 240 |

83.5 |

|

|

2.0 |

120 x 240 |

92.7 |

TPI BOARD for CEILING

TPI Ceiling Boards have special attributes including flat and smooth surface, lightweight, easy-to-install and the ability to withstand all weather conditions because the boards are composed of the fire and humid retardant materials. Therefore, the ceiling boards can be used for both interior and exterior applications. Besides, there is no asbestos in TPI Ceiling Boards, thus, it is ensured that the residents are safe from the respiratory diseases caused by inhaling asbestos – containing dust.

|

Edge |

Thickness (cm.) |

Dimension (cm.) |

Weight (kg.) |

|

Smooth Edge |

0.4 |

60 x 60 |

2.2 |

|

0.4 |

60 x 120 |

4.3 |

|

|

0.4 |

60 x 240 |

8.6 |

|

|

0.4 |

120 x 120 |

8.6 |

|

|

0.4 |

120 x 240 |

17.2 |

|

|

0.6 |

120 x 240 |

25.8 |

TPI BOARD for PANELING

With the contemporary technology, toughness and elasticity are combined together to become TPI Paneling Boards that have exceptional characteristics including lightweight, high resistance against heat and humidity, and sonic insulation. The paneling boards are adjustable and can easily be painted, tiled, and plastered as required

|

Edge |

Thickness (cm.) |

Dimension (cm.) |

Weight (kg.) |

|

Smooth Edge |

0.6 |

120 x 240 |

25.8 |

|

0.8 |

120 x 240 |

34.4 |

|

|

1.0 |

120 x 240 |

43.1 |

|

|

1.2 |

120 x 240 |

51.7 |

|

|

Recessed Edge |

0.6 |

120 x 240 |

25.8 |

|

0.8 |

120 x 240 |

34.4 |

*Can be used for both interior and exterior applications

|

|

|